Method 1A—SAMPLE AND VELOCITY TRAVERSES FOR STATIONARY SOURCES WITH SMALL STACKS OR DUCTS

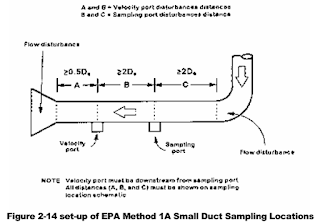

This procedure is the same as that in Method 1, except for the special provisions that apply to small stacks or ducts where 10.2 cm (4 in.) D 30.5 cm (12 in.), or for small rectangular ducts where 81.1 cm2 (12.57 in.2) A 729 cm2 (113 in. 2). A standard type pitot tube must be used for the velocity measurements and must NOT be attached to the sampling probe. In these small diameter stacks or ducts, the conventional Method 5 stack assembly (consisting of a Type S pitot tube attached to a sampling probe equipped with a nozzle and thermocouple) blocks a significant portion of the duct’s cross-section and causes inaccurate measurements. Therefore, for particulate matter sampling in small ducts, the gas velocity is measured either:

- Downstream of the sampling nozzle (for unsteady flow conditions), or

- In the same sample port alternately before and after sampling (for steady flow conditions).

The procedure for determining sampling location, traverse points, and flow rate (preliminary or other) in a small duct is as follows:

1. Select a site as shown in Figure.

2. Use Method 1 to locate traverse points for each site and choose the highest of the four numbers for traverse point number.

3. For PM (steady flow) or velocity (steady or unsteady flow) measurements, select one location and use the same criterion as Method 1.

4. For PM (steady flow) conduct velocity traverses before and after PM sampling to demonstrate steady state conditions, i.e., within ± 10% (vf/vi <1.10).

5. For PM (unsteady flow), monitor velocity and sample PM at two separate locations simultaneously.

0 Comments